Description

General

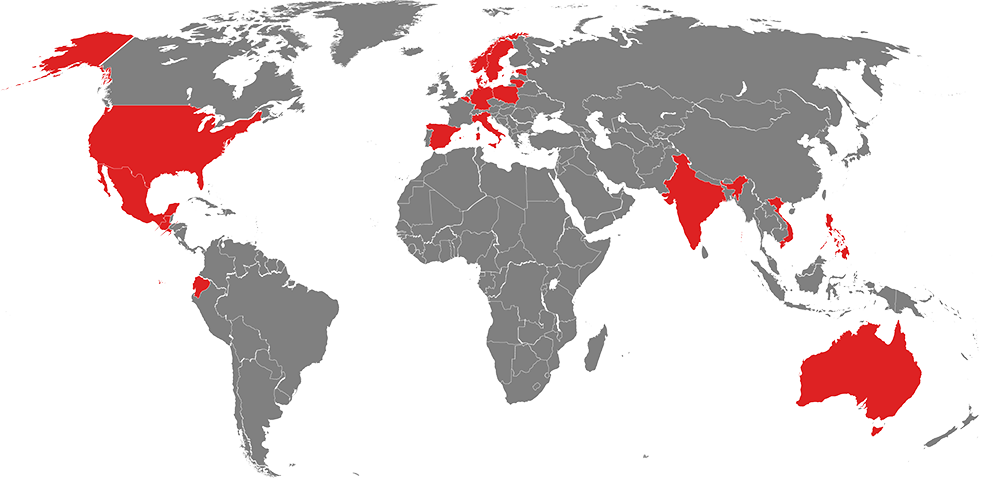

The patented design works just as well in -30 degrees snow and ice conditions as in +50 degrees tropical environment.

The TWO is made of stainless steel and high-quality Aluminum it will not rust or corrode. There is either no hydraulics that may freeze or leak or get worn.

The TWO can be mounted directly on a vehicle or pre-installed on a special trailer. Both installations are available with optional self-wetting system required for pavement maintenance purposes.

There are solutions for mounting in line with left or right vehicle wheel track – or in between.

The software is installed in a laptop located at the driver seat. It will handle measurement, display and store data. The program ensures easy operations, collects results and enables reporting of details immediately after the measurements are performed.

Elegantly mounted on the vehicle, easily detachable.

Alternatively mounted on a trailer.

How it works

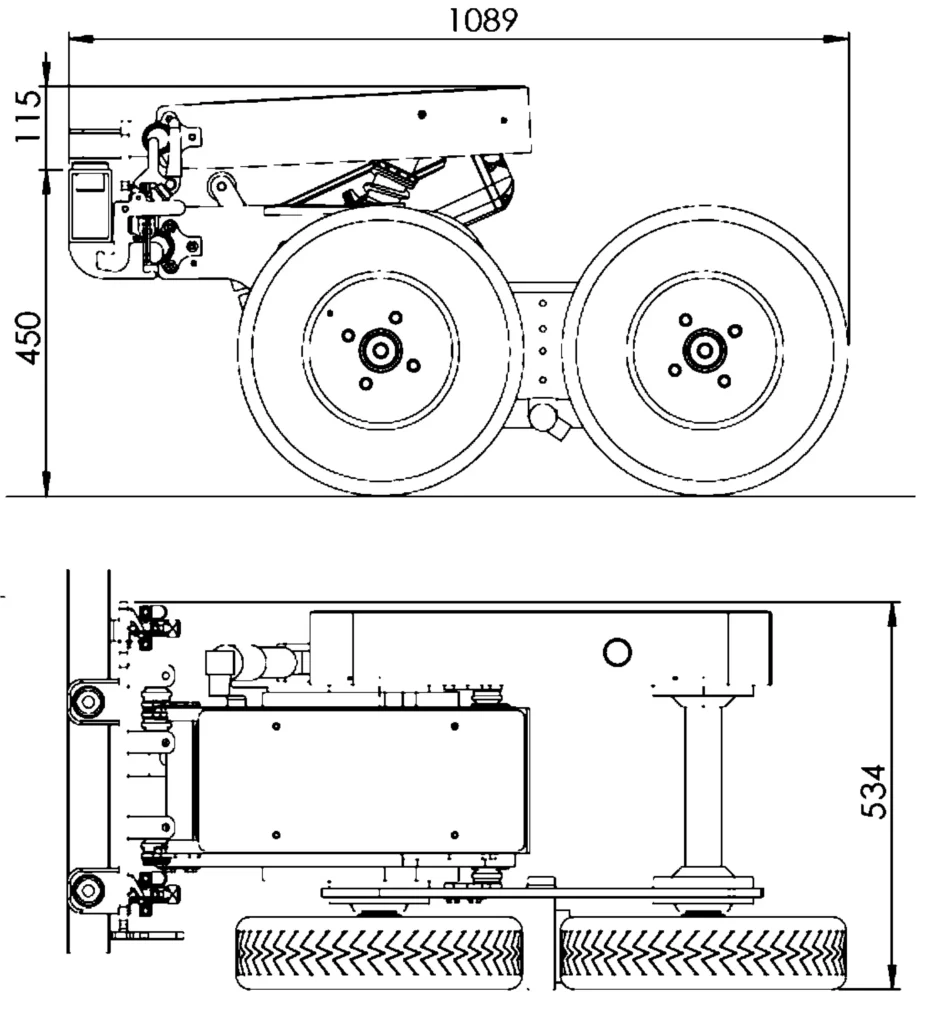

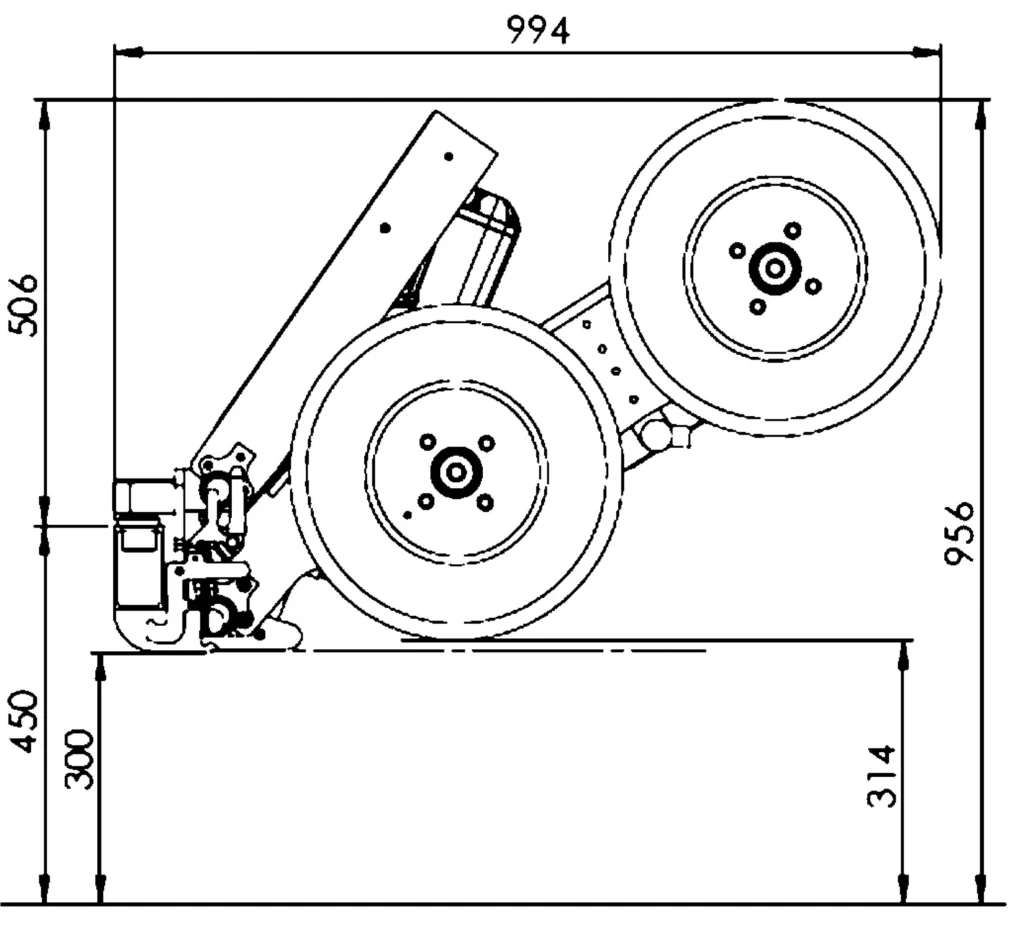

The unit is raised and lowered by an electric actuator that is controlled by the TWO software. In upper position the TWO is free in the air and not in contact with the surface below. This is the normal position when moving between sites.

When lowered the device is pushed to the ground at a preset force by the electric actuator. The down force is measured and automatically controlled by the software.

The 2 wheels are connected mechanically by a chain. Front wheel has about twice the down force as the rear wheel. That makes the front wheel the driving wheel and is running at the same speed as the vehicle.

The rear wheel is the measuring wheel and driven by the driving wheel via the chain, but is geared so it is rotating 17.8% slower than the driving wheel.

Friction level is recorded at 100Hz and is calculated by dividing measuring wheel down force (Fd) by the measuring wheel braking force (Fb); Friction coefficient = µ =Fd/Fb.

Roads winter

Provide information to the maintenance personnel whether salting or sanding is required to ensure sufficient friction and safe driving conditions. Measurement usually made in the vehicle left wheel track.

Both vehicle mounted and trailer mounted TWO is suitable.(Fb); Friction coefficient = µ =Fd/Fb.

In winter measurement service for over 20 years.

Airport winter

Knowing that the runway surface can provide sufficient braking friction for a landing aircraft is essential for safety. There is no room for error. In bad weather the friction level may change rapidly, sometimes significantly in 10-20 minutes, so friction measurement data must be fresh.

Both vehicle mounted and trailer mounted TWO is suitable.

TWO CFME – Continous friction measuring equipment Approved by FAA.

Why measure?

Safety!

No road, runway or pavement is getting better by friction measurement. But knowing the condition of the surface is essential for knowing when to make an intervention.

Saving money!

An old saying: “If it’s not broken why fix it?” Making a friction measurement is a lot cheaper than making rubber removal, remake the surface- or in winter, spreading expensive chemicals or salt.

Saving the environment!

Thousands of tons of salt and chemicals are being used every year to improve friction level. It represents a significant stress on the environment and often pollutes the ground water. Is the intervention always required or is the action based on ‘believing’ and ‘feeling’ of that something needs to be done?(Fb); Friction coefficient = µ =Fd/Fb.