Description

General

ViaFriction is a one-wheeled friction measuring device pulled by a vehicle. It is designated a CFME (Continuous Friction Measuring Equipment). Its main task is to measure the friction of the pavement surface. The friction between the measuring wheel and the surface is continuously measured, while a unique measuring technology, developed and patented by ViaTech, ensures that the data is stable and reliable, even under volatile conditions. This reduces the need for calibration significantly.

The device has very few moving parts — which makes ViaFriction less prone to mechanical failure. ViaFriction uses an electric braking system to be able to measure the friction coefficient.

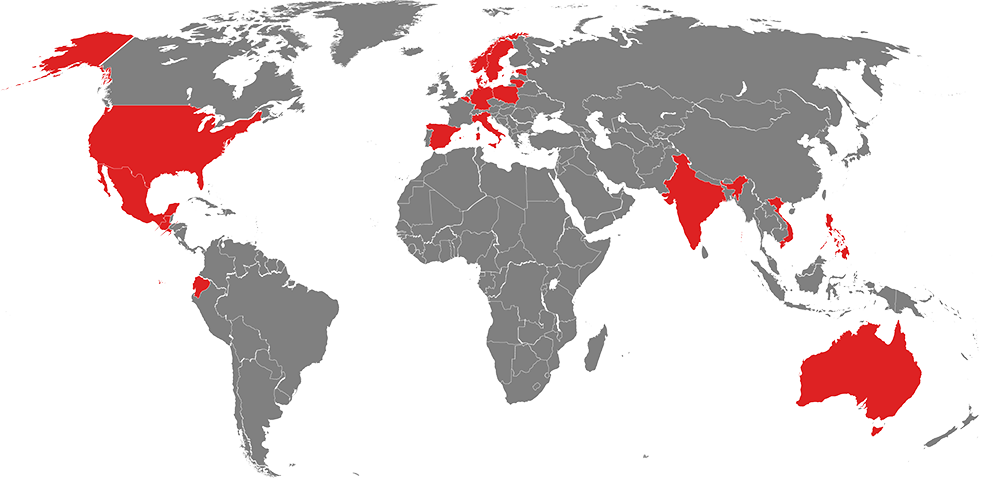

Through rigorous testing, it has been proved that ViaFriction has superior characteristics compared with other friction testers on the market. ViaFriction gives repeatable measurements for various conditions and retains its calibration over time. Our customers range from universities to road authorities and private companies around the world.

The friction measurement device is attached to a trailer or to the vehicle itself. ViaFriction is delivered with an electric lifting device, which will elevate the measurement unit above the road surface when not in use. See the images for an illustration of this lifting mechanism. ViaFriction communicates with the computer in the car using a wireless link or an Ethernet cable. The trailer solution makes the friction meter independent of one specific vehicle and does not require vehicle-specific installation.

Trailer with 1000 litters of water, gives 30km measurement range

Truck with 2000 litres of water gives 60km measurement range

Technology

The measured friction and friction force depends on the normal force on the measure wheel, and the speed difference in between the measure wheel and the vehicle. In order to obtain accurate measurements, it is important to have an accurate control of the speed and a good measurement of the normal force.

Most friction testers currently on the market have a fixed speed difference in between the measure wheel and the vehicle. ViaFriction uses an electrical brake to control the speed of the measuring wheel. The brake is controlled by a computer. This solution results in a control system with extremely low response time and an accurate control of the speed of the measuring wheel. It also allows measurement modes not possible for devices on the market today. This includes the Variable Slip and Surveillance Mode. These modes are not available from other vendors (such as SCRIM, Griptester, MuMeter etc.)

An advanced suspension system on both the trailer and the measurement unit ensures that the measure wheel has a good grip on the road surface, and that the driving is comfortable, even on uneven roads.

Standards

ViaFriction conforms to the following standards:

- ASTM E2340: Continuous fixed-slip measurement

- ASTM E1551-08: Smooth test tire for fixed-slip friction testing

- CEN TS 15901-14:2016: Procedure for determining the skid resistance of a pavement surface using a device with longitudinal controlled slip

- ASTM F408-99: Standard Test Method for Tires for Wet Traction in Straight-Ahead Braking Using a Towed Trailer

Summer measurement

It is very important that the water film used to cool the tire is constant and has an even thickness (0.5mm on roads 1.0mm on airports). It is also important that the water spray does not wash the road surface for contaminants. The advanced pump system measures the vehicle speed and calculates the the correct water speed, so that no washing action is done.

Devices delivered for all-year operation will include a water tank for this purpose. The tank may be placed inside the car, or — if a bigger tank is needed — in a separate trailer. In the case of a separate trailer, the ViaFriction may be mounted directly on the trailer.

Winter measurement

Winter measurements will expose the device to low temperatures, salt, gravel, etc. ViaFriction is built from the highest-quality materials and components to ensure optimal results, even in the unforgiving winter environment. The heat that ViaFriction produces under operation will keep the device free of ice and snow.

Running during the winter does not require the watering system explained above.

Mounting

As an independent device, ViaFriction may be mounted in a number of fashions. Some of the possible configurations are listed below; though, more are possible. The slideshow to the right illustrates the mounting options. Contact our sales department for more info about custom mounting.

The device may be mounted

- On a summer trailer including a water tank, EU CoC.

- Underneath a truck

- Directly on the back of a vehicle

A more advanced option is possible for covering split friction where 2 (or even 3) ViaFriction measuring units covers both the left and right wheel path, and the optional third, the center path.

Measuring Modes

ViaFriction supports several measurement modes such as fixed slip, variable slip and surveillance.

Fixed slip

The fixed slip mode is when the measure wheel speed is a percentage of the vehicle speed. This is identical to measurement modes used by most friction testers. In order to obtain repeatable results in fixed slip, the measurement must be performed in a fixed speed. The measured friction varies with the speed difference in between the measure wheel and the vehicle.

Surveillance

The surveillance mode is a variant of the fixed slip mode where the actual friction measurement does not take place unless the friction level is below a given value. The surveillance mode greatly reduces wear on tire and apparatus.

Variable slip

The Variable slip mode measurement is achieved by conducting wheel braking from free rolling to almost fully-locked and measuring the breaking friction force which the road surface exerts against the breaking wheel.

User Interface

The driver operates the ViaFriction friction tester using a Windows PC program. Normally the program is running on a lap-top, but can also be on a stationary PC mounted in the vehicle. The program can, in addition to the normal PC interface, be operated using a small button panel mounted close to the steering wheel. The measurements can be transferred via mobile broadband from the

vehicle to the decision-makers in real-time to ViaWEB. The measurements can then be analysed using ViaPlot+ or Microsoft Excel. Recording of friction measurements is often combined with ViaPhoto for documentation of the road standard and executed maintenance work.

Technical specifications

| Physical dimensions | |

|---|---|

| Dimensions (trailer version) | Height: 1860 mm, Length: 4780 mm, Width: 2160 mm (73.2, 188.2, 85.0 in) |

| Dimensions (friction meter only) | Height: 830 mm, Length: 1150 mm, Width: 405 mm (32.7, 45.3, 15.9 in) |

| Weight (trailer version) | 2050 kg, inc. 1000 kg water (4520 lbs, inc. 2200 lbs water) |

| Weight (friction meter only) | 80 kg (132 lbs) |

| Measurement speeds | |

| Measurement speed: | 20 – 95 km/h (12 – 60 mph) |

Fixed Slip

The slip percent can be set to any percentage from 1% to 75%. Typically slip percentage during measurements is 20% under winter conditions and 18% under summer conditions.

| Variable slip | |

|---|---|

| µ-peak | Variable slip friction value, calculated at the peak effect of the braking measuring wheel. |

| F60 | The friction value at 60 km/h slip speed. |

| F30 | The friction value at 30 km/h slip speed. |

| Sp | The speed/friction curve slope at the F60 point, alternatively the F30 point. |